|

<< Click to Display Table of Contents >> Redundancy reduction |

|

|

<< Click to Display Table of Contents >> Redundancy reduction |

|

Redundant information is double information, unnecessary information, information that you can get from somewhere else and which is therefore of no additional value.

With the aid of the redundancy reduction you can shorten the item designations in the circuit diagrams. The item designation specification made in the attributes of a symbol, is interpreted together with specifications in the title field, and possible specifications in boundary boxes. Together that gives an unambiguous complete item designation. The item designation parts for which you can apply redundancy reduction are function (plant), location, product (circuit), and sheet.

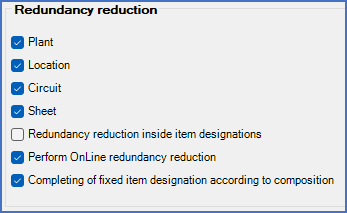

Figure 418: The "Redundancy reduction" section

The settings that you make in this section control the redundancy reduction for:

•Item designations for conventional devices

•Item designations for terminals

•Item designations for PLC's

•Item designations for cables (cable numbers)

•Potential reference names

An Example of how redundancy works is found in a separate sub-topic named just that. You reach that sub-topic using the link. Please check that out!

In the Redundancy reduction section, you specify how redundant designation parts should be removed.

There are seven check-boxes available to control the redundancy reduction feature. You can activate or deactivate each one of them individually.

They are:

•Redundancy reduction inside item designations

•Perform OnLine redundancy reduction

•Completing of fixed item designations

Plant, Location, Circuit and Sheet control whether or not those respective parts of item designations or potential reference names should be subject to redundancy reduction or not.

Redundancy reduction inside item designation controls how the redundancy reduction should be performed, by specifying if each part should be handled separately without considering other parts, or if the reduction should be made from left to right stopping at the first part that is not redundant.

Perform OnLine redundancy reduction acts like an "on/off switch" that controls if redundancy reduction should be made or not.

Completing of fixed item designations specifies if fixed item designations should be converted to complete item designations, meaning if existing item designations should be interpreted with the surroundings in mind. This feature must always be active to achieve a conventional handling of item designations. Automatic item designation generation, for instance, requires that. Automatic item designation generation with this feature inactivated would give an invalid result.

Warning!

Here you have an exceptionally flexible and powerful tool that allows you to follow company specific regulations and ”standards” for item designations. This flexibility, however, demands some level of foresight and precision when working with this.

Some configurations can for instance lead to item designations being shortened so much that they are unidentifiable and their ambiguity thereby being lost. The result is also depending on the composition of the item designations and on whether or not separator character independent item designations are used.