|

<< Click to Display Table of Contents >> Overall sorting |

|

|

<< Click to Display Table of Contents >> Overall sorting |

|

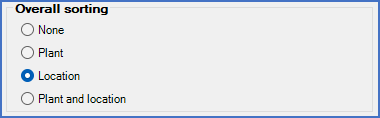

Figure 472: The "Sorting" section

This setting is fundamental for wiring optimisation and wire numbering. For that reason, it is important to pay necessary attention to it, and to carefully consider the consequences of the choice that you make.

Wires must for natural reasons be connected in a certain sequence within each electrical node. That sequence can be more or less optimised. A better optimisation leads to shorter wires, and a happy electrician.

By using any relevant information that is available, the automatic wiring and wire numbering that is done by the OnLine Engine and the Dynamic OnLine, sorts the connections within each electrical node in multiple levels. The parameter that is discussed here, controls the sorting on a high level. To put it in a popular and somewhat over-generalised manner, we are talking of sorting on a cabinet level, not a device level.

Sorting on device level is of course also performed, but as already hinted, that is on a lower level not controlled by this parameter.

For natural reasons, one of the best, if not the best, way of finding the optimal wiring, is to base the calculation on the cabinet layout. Another project parameter - Sub-sorting controlled by cabinet layout - controls whether an attempt to do so should be made or not. If the cabinet layout is not taken into account, the table below describes the criteria that are used to define how connection points should be sorted for the wiring.

The corresponding criteria when cabinet layout information is used, are described in the Sub-sorting controlled by cabinet layout topic.

Priority |

Description |

|---|---|

1 |

The first item to sort on, is what is defined by the setting of the Sorting parameter (the one discussed here).

•The most common choice is Location. That means that wiring is made within each location (cabinet) in first hand, and in second hand to other locations. In other words, the wiring is made in a way that minimises wires between locations.

•If you choose Plant, wiring is made primarily within each plant (function), disregarding the location designation, and secondarily to other plants (functions). This is a less common choice, since function in most cases has very little to do with physical location and therefore with wiring optimisation. This is however totally dependent on the implementation of the item designations.

•If you choose Plant and Location, wiring is made primarily within each combination of plant and location, and secondarily to other such combinations. This choice is most suitable where locations are seen as parts of plants, instead of being completely independent of them.

•If you choose None, neither plant/function, nor location, will be taken into account for the sorting. The component type letter code will have the highest priority in that case. That setting might make sense in small projects that cover only one single cabinet.

|

2 |

The second item to sort on, is the component type letter code from the symbol. Sorting on that is not made alphabetically. The mutual order between component type letter codes is instead defined by the database file NZ.DBF, which is located in the local workstation directory (the WS directory). Consequently, the wiring order between component type letter codes can be changed by editing the NZ.DBF database.

Technical note

To edit NZ.DBF, you need a separate database editing tool, like DBFview Plus or similar. Please note that tools like Microsoft Excel or similar, must not be used to edit DBF files. If you do, the databases will be corrupted, which prevents further use of them.

|

3 |

The third item to sort on, after component type letter code, is the reduced item designation. If plant/function and/or location is part of the complete item designations, those parts are removed. What is left, is the reduced item designation, which sorting is made on. The reduced item designation is divided into the parts of which it consists, like separator character, component type letter code and counting number. Sorting is made alphabetically on component type letter code and numerically on counting number.

If the item designations are such that the parts are unambiguously separated from each other, this division works in a correct manner. If the parts can not be separated from each other in an unambiguous way, no division is made and the entire item designation is sorted unprocessed. This can lead to inconsistencies in the sorting. That fact is yet another strong argument for investing in a well-planned item designation composition and configuration.

Component type letter code appears twice here (both with priority 2 and as part of priority 3), which might seem confusing. However, there is in fact two different component type letter codes. The first one, used as priority 2, is the one that is defined in the symbols and which in a way defines the type of component (like "M" for a motor or "F" for a fuse). The second one, used as part of priority 3, is the letter or combination of letters that is used in the item designation, and which may deviate from the definition in the symbol. A motor that is called "-A1" for example, will have "M" as "symbol component type letter code" but "A" as "item designation component type letter code".

|

4 |

The fourth item to sort on, is the connection point number. The connection point numbers are divided into their letter and digit parts, where the letter parts are left justified and the digit parts are right justified.

A1, A2, A3, A4, A5, A6, A7, A8, A9, A10, B1, B2, B3, B4, B5, B6, B7, B8, B9, B10

|

If Sub-sorting controlled by cabinet layout is activated, sorting is made differently. Please refer to the description of that project parameter for a full explanation.